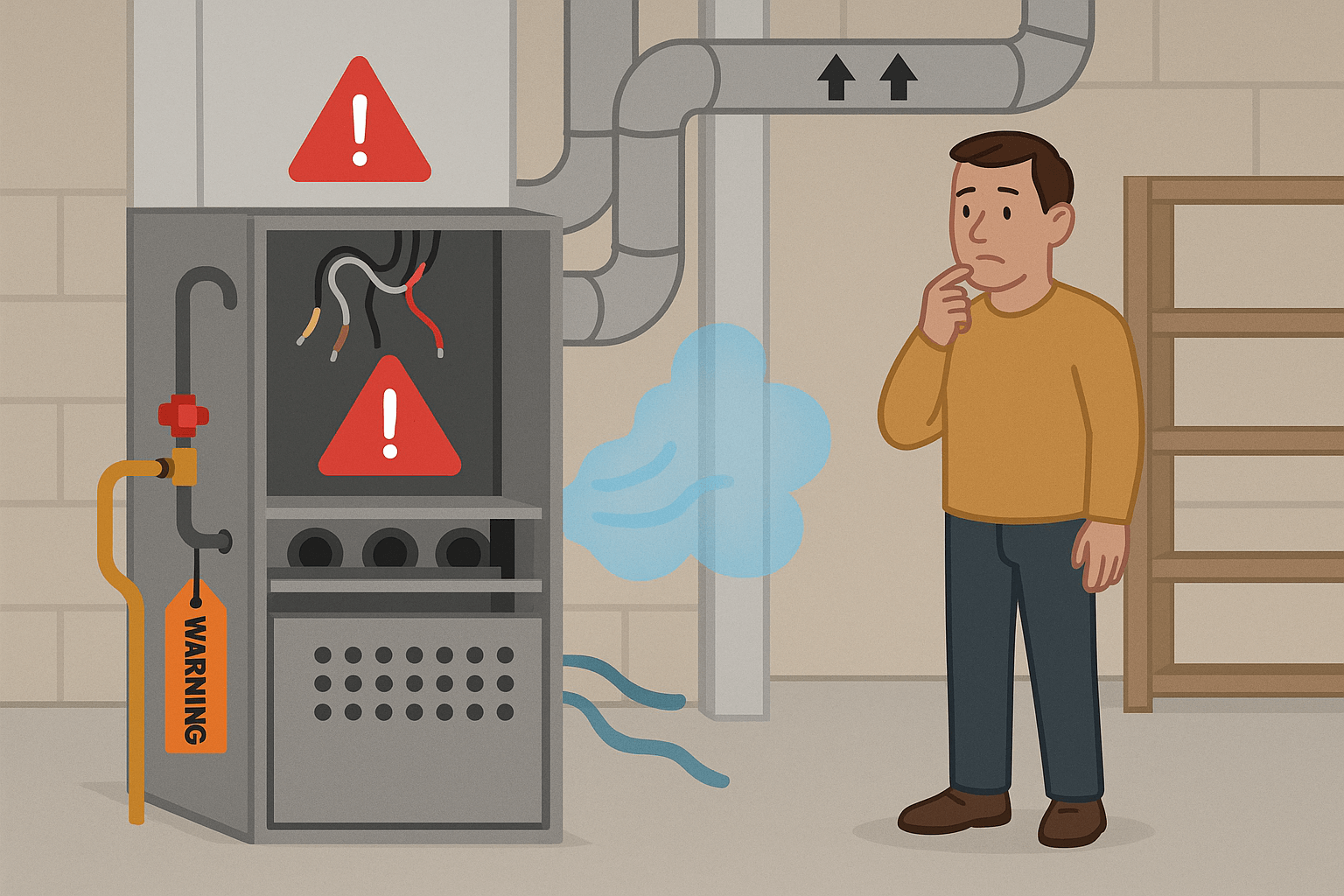

Installing a furnace is a complex process that involves much more than connecting a few parts. While some homeowners search for diy furnace installation risks to decide if the job is worth attempting, the reality is that it can introduce serious safety issues, efficiency problems, and long-term costs. The risks often outweigh any initial savings, making it important to understand what can go wrong before starting such a project.

Understanding DIY Installation Risks for Furnace Systems

Modern heating systems are designed with precise requirements for airflow, electrical wiring, and gas line connections. These need to meet local building codes and safety standards. When those details are overlooked, it can lead to poor system performance, hidden hazards, and even legal issues with code compliance.

Professional installation accounts for all these factors and ensures the furnace is matched correctly to the home, vented properly, and tested for safe operation. Without this, the chances of future malfunctions or costly breakdowns are far greater.

Common Mistakes Homeowners Make During Installation

Rushing into DIY furnace work may look like a way to save money, but common mistakes can create major safety and efficiency issues:

Choosing the wrong furnace size

Selecting a unit that is too large or too small for the home is one of the most frequent DIY furnace installation risks. An oversized furnace often short cycles, wasting energy and causing uneven heating, while an undersized unit struggles to maintain comfort. Both situations lead to higher heating bills, strain on the system, and unexpected costs for furnace repairs down the line.Misunderstanding wiring or gas line connections

A furnace installation involves more than attaching a few parts. Electrical wiring and gas lines must be connected safely and precisely, and the requirements can differ depending on whether you have a gas or electric system . Mistakes here can result in fire hazards, carbon monoxide leaks, or a system that will not run reliably. Homeowners without proper training may unknowingly create dangerous conditions that put their property and family at risk.Overlooking permits, codes, and local regulations

DIY installation projects often skip the legal requirements for permits and inspections. Local codes are in place to ensure that furnaces are installed safely and efficiently, protecting both homeowners and their neighbours. Ignoring these rules can lead to fines, unsafe operation, and problems if the home is later sold.Skipping proper venting or mismatching ductwork

Air circulation plays a critical role in furnace performance, but DIY work often neglects correct venting and duct design. Poorly connected ducts or blocked return pathways can cause airflow issues, reduce indoor air quality, and shorten equipment life. In the worst cases, improper venting can allow carbon monoxide to build up inside the home, creating a serious health hazard.

Even small tasks, such as attempting minor furnace repairs, can damage components or void warranties. Furnaces need balanced air circulation, correct sizing, and professional safety checks, details that are easily missed when installations are attempted without experience.

The Threat of Carbon Monoxide and Home Safety Concerns

Attempting a furnace installationwithout the right training and tools does more than reduce efficiency. It can create dangerous conditions inside the home. One of the most serious risks is carbon monoxide exposure. This gas is invisible and odourless, yet even small carbon monoxide leaks can have severe effects on health, ranging from headaches and nausea to life-threatening poisoning.

When a DIY furnace installation is carried out incorrectly, several issues can allow carbon monoxide to enter the living space. Poorly aligned combustion chambers, blocked flues, or skipped safety checks all increase the likelihood of harmful gases escaping. In addition, neglected venting or inadequate air circulation disrupts proper exhaust flow, raising the risk of leaks. These hazards often go unnoticed until symptoms appear, making prevention essential.

Professional maintenance and correct furnace installation are the most effective safeguards. Certified technicians fit equipment according to safety standards and test for leaks while monitoring indoor air quality. They check airflow, ensure vents are sealed, and confirm that exhaust gases are safely directed outside. For homeowners, choosing to avoid DIY reduces the risk of hidden dangers and ensures that the heating system provides safe, reliable comfort throughout the year.

How Professional Furnace Installation Prevents Dangerous Leaks

Carbon monoxide leaks often occur because of venting mistakes, poor seals, or incomplete safety checks. Even a minor error in duct connection or combustion alignment can result in emissions escaping indoors. Professional furnace installation significantly reduces these risks through a detailed process that focuses on safety and performance:

Proper venting and exhaust alignment

Technicians ensure that combustion gases are directed safely outdoors by aligning flues and venting systems correctly. This prevents backdrafts and reduces the chance of carbon monoxide leaks inside the home.Sealed connections and ductwork checks

Every joint and connection is inspected and sealed to stop harmful gases from escaping into living spaces. Tight ductwork also supports efficient airflow and better indoor air quality.Calibration of gas flow and ignition systems

Incorrect gas flow is one of the leading causes of poor combustion. Professional installers calibrate ignition systems and fuel delivery to maintain efficiency and prevent incomplete burning that could release carbon monoxide.Comprehensive safety inspections

Licensed experts carry out safety tests after installation, including checks for leaks and ventilation blockages. These inspections confirm that the furnace is operating within safe standards before it is put into use.Ongoing professional maintenance

Regular tune-ups and inspections by certified technicians help detect potential issues early. This proactive approach ensures long-term reliability and reduces the risk of dangerous leaks over time.

Why Proper Air Circulation Matters for Efficient Performance

A furnace cannot perform at its best without correct air movement. Poor circulation causes hot and cold spots around the home and forces the system to work harder, increasing energy bills and wear.

DIY work often overlooks details such as duct sizing, vent positioning, and return pathways. When airflow is restricted, it can shorten equipment lifespan and reduce overall comfort.

Professional design ensures that air is balanced, heating is distributed evenly, and the system operates efficiently. Good circulation not only keeps energy use under control but also supports better indoor air quality and long-term system reliability.

Making the Safe Choice for Your Home

Furnace installation is about more than fitting new equipment. It affects safety, air quality, energy costs, and comfort for years to come. While DIY attempts may seem appealing at first, the risks are significant and the long-term benefits of professional support are clear.

If you are considering a new furnace or worried about the performance of your current system, reaching out to a trusted local HVAC professional can provide the reassurance and expertise needed to keep your home warm and safe.